Maltodextrin Powder Description

Maltodextrin Powder (CAS 9050-36-6) is a polysaccharide produced by the partial hydrolysis of starch. Composed of D-glucose units, it features a controlled molecular profile that ensures predictable solubility and easy blending into various formulations. It acts as an effective texturizer and provides a source of digestible carbohydrates, making it a versatile ingredient for meeting precise requirements in food processing.

Maltodextrin Powder Specifications

| Parameter |

Value |

| CAS Number |

9050-36-6 |

| Color |

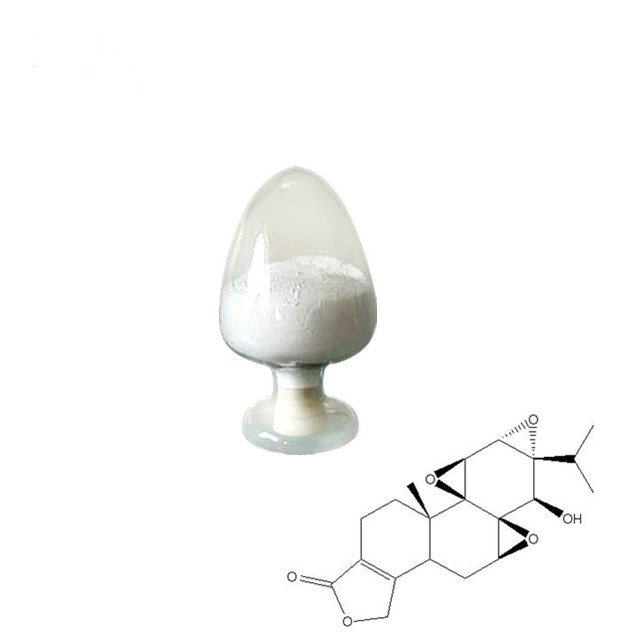

White |

| Form |

Powder |

| Biological Source |

Corn |

| Melting Point |

240℃ |

Maltodextrin Powder Applications

1. Food Processing:

- Bulking & Carrier Agent: Serves as an excellent base for powdered beverages, instant mixes, and spices, ensuring uniform consistency and rapid dissolution without clumping.

- Texture Modifier: Imparts a smooth mouthfeel and desired consistency in snacks, sauces, and dairy products, effectively improving overall sensory quality.

- Fat Replacer: Can be used in low-fat formulations to mimic the mouthfeel and texture typically provided by fats.

2. Nutritional Products:

- Energy Source: Provides a source of easily digestible carbohydrates in sports drinks, weight gainers, and clinical nutrition products, helping to tailor precise energy content.

- Functional Filler: Acts as a neutral carrier for flavors, colors, and sweeteners in supplement formulations, ensuring even distribution and stability.

Maltodextrin Powder Packing

To guarantee product integrity, our Maltodextrin Powder is packaged in high-quality, moisture-resistant, food-grade liners housed within sturdy outer packaging. All containers feature tamper-evident seals for safety. We offer a range of packaging options, from flexible pouches to rigid drums, tailored to meet your volume and handling needs. Custom labeling is available to comply with specific industry and regulatory standards. For optimal shelf life, store in a cool, dry environment.

Frequently Asked Questions

Q1: How does the production process affect Maltodextrin's solubility?

The controlled hydrolysis process during production determines the Dextrose Equivalent (DE) and molecular weight profile. This precise control results in predictable and rapid solubility, which is critical for uniform performance in liquid systems and dry mixes.

Q2: What quality control ensures consistent product quality?

Our production employs rigorous Quality Control (QC) protocols, including advanced chromatographic analysis to verify the carbohydrate profile and consistent DE value. Additionally, we conduct thorough solubility, moisture, and microbiological testing to ensure every batch meets stringent specifications for performance and safety.

Q3: Can Maltodextrin be customized for specific applications?

Absolutely. By adjusting the hydrolysis parameters, we can produce maltodextrins with different DE values, thereby tailoring functionality such as sweetness intensity, solubility rate, and texture-modifying properties to meet specific formulation requirements.

Additional Information

Maltodextrin is a polysaccharide produced through the partial hydrolysis of starch, resulting in a mixture of glucose polymers. Its versatility as a food additive stems from its neutral taste and a suite of functional properties, including its role as a bulking agent, carrier, and texture enhancer.

The relationship between the degree of hydrolysis (indicated by the DE value) and the resulting functional properties is a cornerstone of food ingredient technology. This understanding allows for the strategic development of tailored maltodextrins that solve specific challenges in food science, from creating low-calorie options to improving the stability and sensory profile of processed foods.